Capacitors Factory since 1989

info@dfcapacitor.com

info@dfcapacitor.com

product quality

Packing specification

Packing way of power capacitor: independent foam box packing, 10pcs in one big package, final packed to be pallets.

Running and starting packaging: independent small paper boxes, 10pcs in a big white paper boxes, 10 big boxes into a carton, final pallet packaging

Packaging, transport,

In order to avoid product damage caused in the process of transportation storage, ensure that the product the security and integrity before used.Products all adopt single independent small box/foam packaging, then packed in corrugated cartons, finally packed in the pallets to ship, to ensure product and its components, parts don't appear during the whole process of handling manual handling, avoid the happening of thrown the product, such as the product is in good condition during transportation, ensure the quality of products.

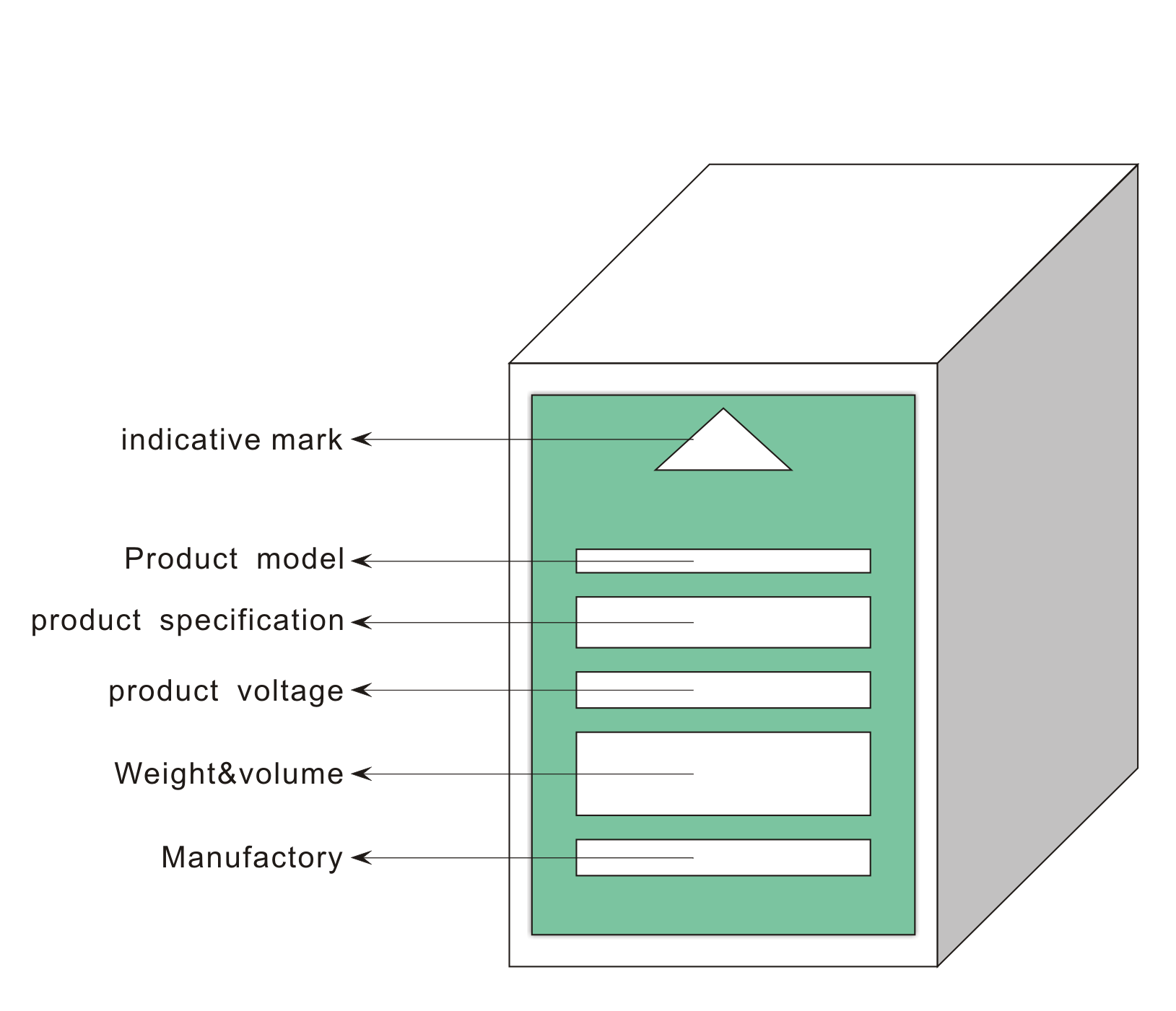

Packaging: identification including label and shipping documents.

Tags: white background and black text, eye-catching specification, format is shown in figure 1

Traceability, follow the principles of seeking truth from facts, to conduct quality controls the source

The selected brands - --northern Europe chemical raw materials, raw material characteristics: high temperature over 85 degrees, raw materials stress high levels

Strive to amount to mark 5000 level evolution i---nto the capacitance film workshop before the wind drench device

Cast slabs device -- in the process of debugging for the first time in a thick slices, learned many German engineers on-site observation, reasoning, methods, ensure that the late flow from source control temperature at a constant speed of particles to cast slabs, put an end to ash gravel, erosion of impurities.

Longitudinal tensile region, the longitudinal tensile is cut into the transverse tensile area, using high speed chain clip, on both ends of the thick slices of transverse stretching smoothly implanted transverse stretching area

Transverse tensile area - on both ends of the chain clamp in the high temperature transverse tensile, fully enclosed environment gradually stretch up to 5.8 meters wide, the high temperature environment in the initial installation is strictly defined its high temperature stability of the closed, especially for heat shrinkage rate of the control.

Transverse stretching to the corona treatment, corona treatment, corona treatment is one of the important factors to maintain film appearance and properties, we adhere to the combination of big data in the area for real-time monitoring, to ensure the thickness uniformity and the decrease of electrical weakness.

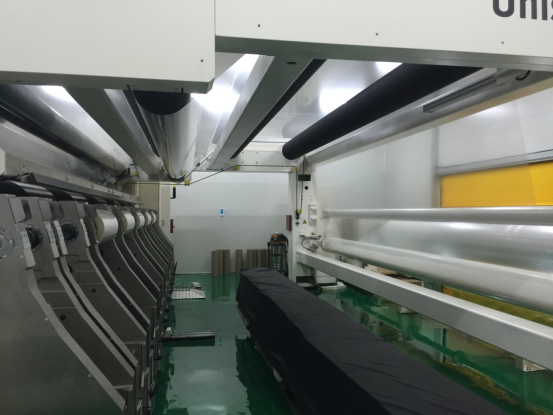

Winding system, in the winding process, ensure the one door is closed, to maintain production line's internal temperature, adhering to the orderly operation, accurate navigation car running in loading and unloading roller link to ensure safety.

Feed from the front - to the very heart of the capacitance mainline, central control room to dissolve, extrusion forming thick slices, thermostat setting, longitudinal and transverse pull, corona treatment, winding system and a series of processes are completed the control room, is controlled by the chief of a section on duty 24 hours in fixed-point observation, timely report the differentiation, chief engineer, engineers at all levels to use rigorous professional technology, good professional dedication make production line standard up to the optimization of capacitance in the film.

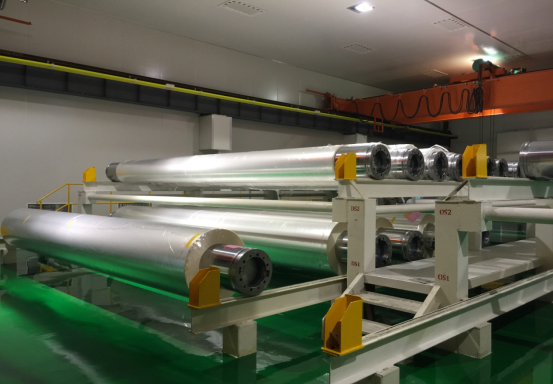

Big roller stacking area -- each winding roller to repeated clean-up before use, to ensure that the burr and scratch, keep the membrane surface roughness.Orderly use label record each volume output time, thickness, poor problem such as real time record

Cutting process, after cutting process performed by the German original kombucha cutting machine, which can realize high speed cutting and 0.5 mu m to 50 microns thin film, is the authority of the cutting and ultrathin membrane equipment all over the world

Cutting process, after cutting process performed by the German original kombucha cutting machine, which can realize high speed cutting and 0.5 mu m to 50 microns thin film, is the authority of the cutting and ultrathin membrane equipment all over the worldcutting and cutting process is designed to ensure that the original film performance, based on the modification on the end surface roughness, the original film hardness, is to determine the base film appearance of weapons, we control the hardness of shaw between 90-92

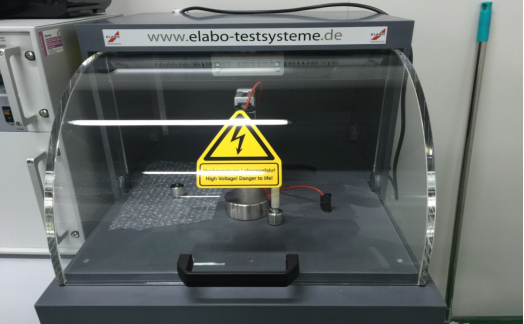

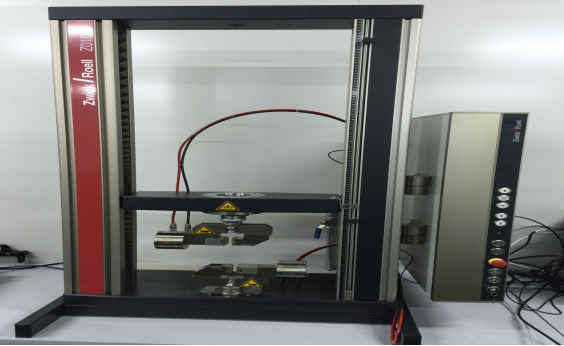

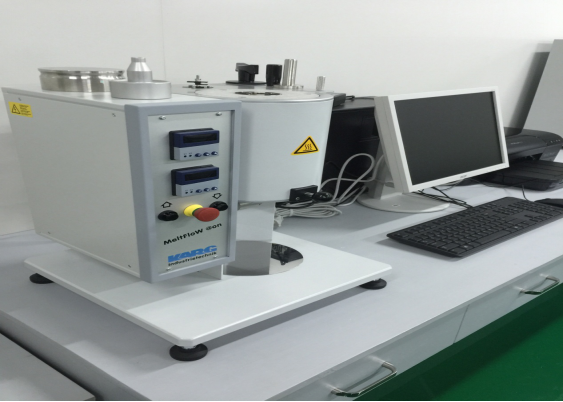

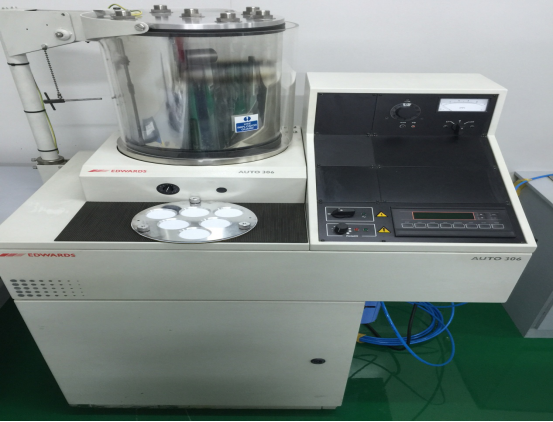

Laboratory, using sophisticated testing instruments, streamline way of testing, to ensure that the membrane volume data is reliable.

(2) the tensile strain gauge equipment

Device (3) oven

Device (4) solution is a meter (in view of the particles in the ash content in the test)

Device (5) vacuum aluminum plating machine (in accordance with the principle of coating after vacuum evaporation with zinc aluminum)

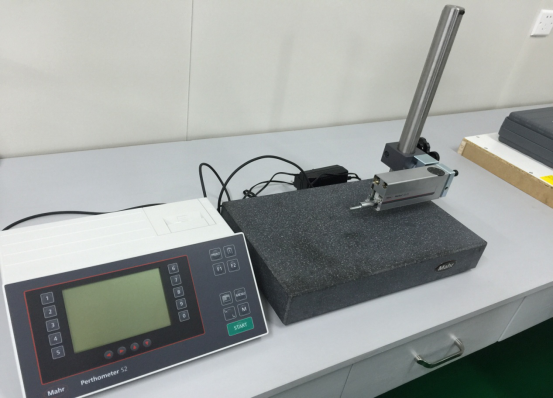

Equipment 6 roughness tester

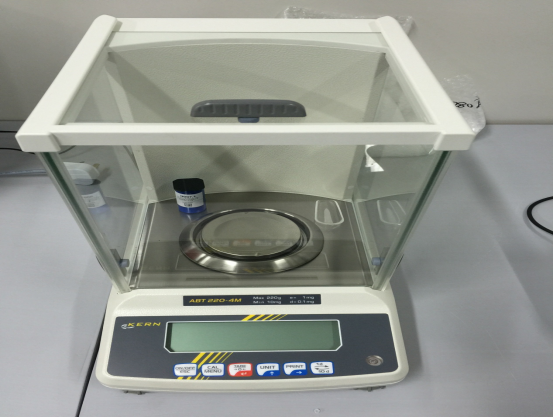

Equipment all landowners electronic balance tester weight (thickness)

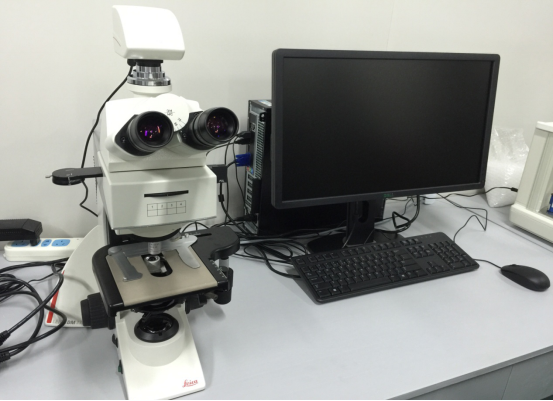

Equipment was microscope (watch film on the surface of the crystal)

Equipment pet-name ruby Mahr thickness gauge (single method base film thickness measurement)

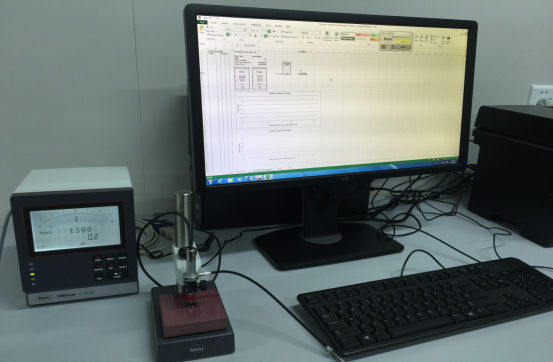

Equipment attending resistance meter (semi-finished product test after evaporation dielectric constant)

Laboratory work

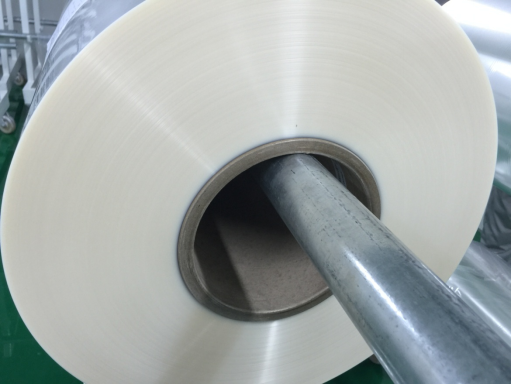

Packaging into library - we rigorously follow capacitance film of various packing, from the core winding to the plastic stopper, plywood, carton each batch comes into play to the strength test, standard packing, after maximum effective to avoid the capacitance of the membrane is damaged, to ensure that the factory product uniformity.